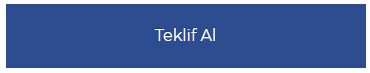

Horizontal Linepack F3M packaging machine is used for packing piece products (biscuits, wafers, marshmallows, burgers, pancakes, bread, soap bars, sponges, etc.) into flow type packs.

PRODUCTS TO BE PACKED:

Biscuits, wafers, marshmallows, bread, burgers, pancakes, soap bars, sponges, pizza, ice cream, cheese, chocolate bars, etc.

Filling Type

| Kinematical speed, max, cycles/min. | 120 |

| Film type | Polypropylene and polypropylene based films |

| Film thickness, mcr | 25-40 (up to 65 depending on conditions) |

| Product width, min, mm | 15 |

| Product width, max, mm | 220 |

| Product length, min, mm | 20 |

| Product length, max, mm | 1000 |

| Product height, max, mm | 120 |

| Film reel width, max, mm | 600 |

| Film reel diameter, max, mm | 350 |

| Film reel weight, max, kg | 25 |

| Roller pairs number, pcs | 2 (3 optionally for pre-heating or seam folding) |

| Film pulling drive unit | Servo |

| Transversal seal drive unit | Servo |

| Transversal seal mechanism | Rotary unit, 1, 2 or 4-position sealing |

| Loading conveyor length, mm | 2000 |

| Power supply | 380 V, 3-Ph, 50 Hz |

| Power consumption, kW | 6,8 |

| Machine length, mm | 3900 |

| Machine width, mm | 1100 |

| Machine height, mm | 2100 |

| Machine weight, kg | 550 |

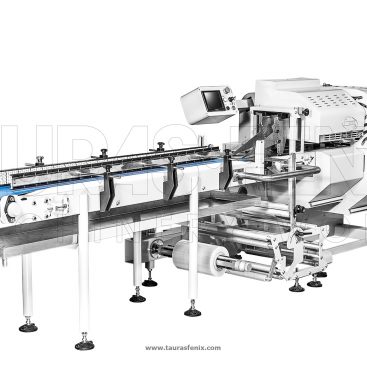

- Machine frame is made of stainless steel

- Feeding conveyor

- Unwinding unit

- Bag forming unit

- Photosensor

- Unit of film drawing and longitudinal sealing

- Cross sealing unit

- Outlet conveyor

- Control panel

- Thermal printer

- Transport tables

- Gathering table

- Rotary, linear or gravity based automatic placer

- Cooling table

- Bag forming unit of special design based on client’s requirements

- Horizontal feeding conveyor of special design based on client’s requirements

- Count of finished goods

- Tray for collecting the crumbs

- Automatic labeler

- Transverse sealing jaws for packaging with 1 cross-seam (for operation with automatic clipping device)

- Transverse sealing jaws for packaging with a perforated (incomplete) cut

- Transverse sealing jaws with euroslot

- Inert gas injection system

- Gusseting device (with pneumatic pushers)

- Zig-zag knife

- Feeding conveyor based on client’s requirements

- Delivery table

- MAP system

- Special output conveyors with lengths of 1000 mm and 1300 mm

- Special input conveyors with lengths of 3000 mm and 4000 mm

- Special bag forming unit for wide and low products

- No product – no bag system