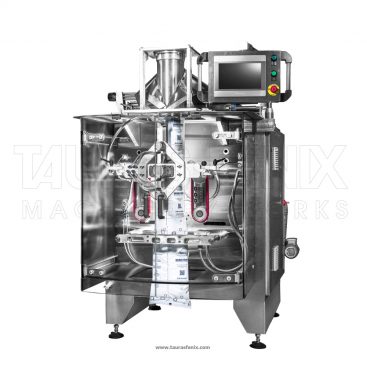

The vertical forming, filling and sealing (VFFS) machine PITPACK M3MN is designed with inclinable frame for delicate packaging of fragile food and non-food products into classic three-seam pillow pouches, bags with flat bottom or into stabilo bags. The machine can be supplied with wide variety of options (euroslot, zip-lock, inert-gas injection, e.t.c) to become your reliable instrument allowing to deliver best marketing experiences to your product on the shelf.

PRODUCTS TO BE PACKED:

- Frozen products: dumplings, pasties, ravioli;

- Confectionery products: crackers, gingerbread, biscuits, dry toasts, dried biscuits, and snacks;

- Non-food products: household detergents, construction materials, pet products, soil and fertilizers, etc.

Filling Type

| Kinematical speed, max, cycles/min. | 90 bags/min |

| Product tube diameter, mm | 490 per drawing cycle |

| Bag width, mm | 85-372 |

| Bag length (single pulling), mm | 490 |

| Film type | polyethylenes, polypropylenes, laminates, barrier films |

| Film thickness, mcr | 40-130 |

| Film reel weight, max, kg | 50 |

| Product tube inclination angle, ° | 45 |

| Film unwinding drive unit | Asynchronous gear motor |

| Film pulling drive unit | Asynchronous gear motor / Servomotor |

| Longitudinal seal drive unit | Pneumatic cylinder |

| Transversal seal drive unit | Asynchronous motor |

| Filler as standard equipment | No filler |

| Power supply | 380 V, 3Ph, 50 Hz |

| Потребляемая мощность, кВт | kWt: 5/7 servo; with edge steaming: 6.5/8 servo |

| Air pressure, MPa | 0.6 |

| Air consumption, l/min | 50 |

| Machine length, mm | 2100 |

| Machine width, mm | 1329 |

| Machine height, mm | 1924 |

| Machine weight, kg | 800 |

| Structure material | Stainless steel AISI 304 |

- Packetizer;

- Transverse quick-release welding jaws for prompt replacement;

- Drive of the transverse welding jaws on the asynchronous electrical engine;

- Cutoff knife in the transverse welding jaws;

- Longitudinal seam blow-off function;

- Electromechanical film draw drive;

- The automatic machine has automatic film stabilization;

- Photo tag sensor;

- Film gluing device;

- Film end sensor.

- Flat bottom former;

- Device for token turn of the bag bottom seam;

- Edge welding device;

- Different welded seam configurations;

- Possibility to mark the date on the transverse seam or on the bag space;

- Former of through cuts on top seams (Euroslots, cut handles, cutting for 3 fingers etc.);

- Device for setting ZIP fasteners;

- Device for making perforations facilitating bag opening (horizontal and vertical);

- Vibrating funnel for packetizer loading.

- Labelling (applying labels on the bag surface);

- Set of welding jaws with pulsed heating;

- System for feeding inert gas/alcohol into bags (to extend the shelf life of confectionary products);

- Statics release system;

- Aspiration system unit;

- Clamps for squeezing excess air out of bags;

- Thermal printer