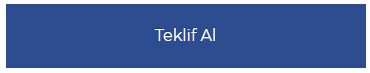

The double-lane weighing batcher is designed to weigh free-flowing and small or medium piece products by weighing out portions with their further discharge. If the products are frozen, the parts in contact with the product are made out of corrugated stainless steel. It is controlled by a microprocessor weighing terminal. All information is put onto a display.

The double-lane weighing batcher can be incorporated into all types of packaging machines of Tauras-Fenix or can be used separately. The principle of weight filling allows the handling of a wide range of products while keeping a high accuracy of filling but for the cost of operational speed. To achieve a higher efficiency it is possible to use three- and four-line weighing batchers, combinational batchers (multiheads), or volumetric batchers (for certain types of products).

Loose, free-flowing and small piece products, with a possibility to dose abrasive products as well. Confectionery: cookies, candies, sushki, spice cakes, etc. Grocery: grains, cereals, macaroni, tea, coffee, sugar, salt, spices (pepper, sweet peas, cloves, bay leaves, etc.). Snacks: chips, nuts, dried fruit, etc. Frozen products: vegetables, berries, mushrooms, seafood, ravioli, etc. Non-food products: detergents, granulated fertilizers, animal food, building materials, etc

Filling Type

| Kinematical speed, max, cycles/min. | 40 |

| Dose weight, min, kg | 0,015 |

| Dose weight, max, kg | 2 |

| Dosing type | Weighing |

| Dosing accuracy | Meets Russian State standards |

| Dosing accuracy for piece products | ± 1 pc. |

| Power supply | 220 V, 1-Ph, 50 Hz |

| Power consumption, kW | 1,5 |

| Air pressure, MPa | 0,6 |

| Air consumption, l/min | 40 |

| Machine length, mm | 1400 |

| Machine width, mm | 1330 |

| Machine height, mm | 115 |

| Machine weight, kg | 230 |

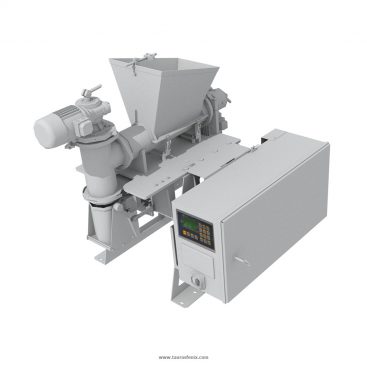

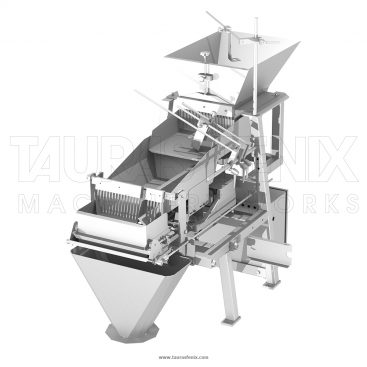

- Weighing bins

- Weigher

- Weighing units

- Control unit

- Empty chute

- Framework with a feeding tank

- Upper vibrating chute

- Lower vibrating chute

- Coarse filling brush

- Adjusting brush

- Adjusting vibrating chute

- Set of sensors to control product’s levels